The manufacturing industry in Latin America faces a unique set of challenges: from economic and political volatility to the need to adapt quickly to changing market demands and sustainability expectations, companies in the region are in a constant search for strategies that will enable them not only to survive but to thrive.

Digitalization emerges as a critical tool, capable of radically transforming the way manufacturing operates, improving its efficiency, innovativeness and competitiveness.

Microsoft Dynamics 365 is presented as a comprehensive cloud solution designed specifically to address these needs. By seamlessly integrating customer relationship management (CRM) and enterprise resource planning (ERP) with advanced artificial intelligence (AI) and data analytics capabilities, Dynamics 365 offers Latin American manufacturing companies the opportunity to revamp their operations and prepare for the future.

The potential impact of implementing Dynamics 365 in day-to-day operations is vast: from optimizing the supply chain to improving customer relationship management and automating internal processes, this system promises not only to increase operational efficiency but also to open new avenues for innovation and sustainable growth.

With Dynamics 365, companies in the region can expect to not only meet on-time deliveries by minimizing warehouse travel time through automated material handling partnerships, customizable work instructions and advanced mobile applications, but also foster a culture of collaboration and operational efficiency throughout the organization.

Manufacturing challenges in Latin America

Manufacturing in Latin America is at an inflection point, where the opportunities for growth and innovation are as abundant as the challenges to overcome. Companies in the region face a complex set of obstacles that can significantly impact their ability to compete globally and meet the demands of an ever-evolving marketplace.

Economic and political volatility: The region is known for its economic and political instability, which can directly affect manufacturing operations. Fluctuations in exchange rates, changes in trade policies and regulatory uncertainties require companies to be extremely agile and able to adapt quickly to new scenarios.

Infrastructure and logistics: Despite progress, many Latin American countries still face challenges related to infrastructure and logistics. Difficulties in transportation and distribution can increase operating costs and affect companies’ ability to deliver on time.

Access to advanced technology: Although there is growing interest in digitization, some companies still struggle to access and adopt advanced technologies. The technology gap can limit their operational efficiency and ability to innovate.

Global competition: Market globalization means that Latin American companies compete not only with each other but also with manufacturers around the world. Staying competitive requires not only high quality products but also efficient operations and a focus on continuous innovation.

Sustainability expectations: There is growing pressure from consumers and regulators for companies to adopt sustainable practices. This includes efficient resource management, reducing environmental impact and implementing ethical labor practices.

Skilled workforce: Finding and retaining skilled talent is another major challenge, especially in areas related to technology and supply chain management. Continuous training and skills development are essential to maintain a competent workforce.

Adapting to changing market demands: Today’s consumers are looking for customization, quality and speed of delivery. Adapting to these changing demands requires great operational flexibility and rapid responsiveness.

An overview of Microsoft Dynamics 365 for Manufacturing

Microsoft Dynamics 365 Supply Chain Management offers an extensive set of features and capabilities that enable organizations to manage their manufacturing operations effectively and efficiently. Below, we detail these features and delve into how they can specifically benefit the Latin American manufacturing context.

Planned production and scheduling

Microsoft Dynamics 365 revolutionizes production planning and scheduling by providing robust tools such as master production scheduling (MPS), material requirements planning (MRP) and capacity planning.

This advanced planning capability enables users to create and manage production orders, optimize resource allocation and monitor work center capacities. The implementation of these tools ensures efficient production processes and on-time delivery of orders, crucial elements for manufacturers operating in the dynamic Latin American market.

Bill of Materials (BOM) and Routing Management

Advanced BOM and routing management in Dynamics 365 enables organizations to define and maintain complex product structures, operations and work center requirements. The ability to create multi-level BOMs, manage revisions and define routes for each operation ensures accurate production planning and accurate cost estimation, directly addressing the need for precision and control in Latin American companies.

Shop Floor Control

Shop floor control features in Dynamics 365 include work order management, work center scheduling and real-time production monitoring. The ability to track production progress, monitor machine utilization and manage production exceptions significantly improves efficiency and visibility on the shop floor, responding to the demand for more agile and transparent operations in the region.

Lean Manufacturing

Supporting lean manufacturing principles and methodologies, such as Kanban and continuous improvement, Dynamics 365 facilitates waste reduction, improves production flow and increases overall manufacturing efficiency. The implementation of lean practices is especially relevant for Latin American companies seeking to optimize resources and processes in a challenging economic environment.

Quality Management

Dynamics 365 offers comprehensive quality management capabilities, enabling organizations to ensure product quality, compliance and safety. Users can define quality tests, inspections and sampling plans, as well as track quality data and generate reports, supporting compliance with industry-specific regulations and customer requirements, crucial for companies looking to expand beyond local markets.

Examples of use in Latin America

The implementation of Microsoft Dynamics 365 for Manufacturing has significantly transformed the operations of numerous companies in Latin America, demonstrating its ability to effectively address specific regional challenges. The following are examples of use and success stories that illustrate the positive impact of this solution in the Latin American manufacturing sector.

Success story: electronic components manufacturing company

A leading Mexican company specializing in the manufacture of electronic components was facing challenges in managing its supply chain and production efficiency due to manual processes and disintegrated systems. The implementation of Dynamics 365 for Manufacturing enabled the automation of production processes and better resource planning, resulting in a 20% reduction in production times and a significant improvement in inventory accuracy.

Usage example: food products manufacturer

A leading Argentine company in the food industry was looking to optimize its operations and improve the traceability of its products to comply with food safety regulations. By adopting Dynamics 365, they were able to integrate their production, quality and distribution operations into a single platform. This not only facilitated regulatory compliance but also improved operational efficiency, reducing waste and improving customer satisfaction.

Success story: textile industry in Brazil

A major Brazilian textile producer was struggling with managing its complex supply chain and wanted to increase visibility into its manufacturing operations. After implementing Dynamics 365, the company experienced a transformation in its ability to plan and execute production, efficiently manage inventory, and respond nimbly to fluctuating market demands. As a result, they achieved a 15% increase in production efficiency and a marked improvement in customer response time.

Usage example: machinery manufacturer in Colombia

A Colombian company dedicated to the manufacture of heavy machinery needed to improve asset management and optimize preventive maintenance to avoid unplanned downtime. With Dynamics 365, they implemented a predictive maintenance system based on sensor data and AI, which allowed them to anticipate machinery failures and schedule maintenance proactively, improving machinery availability and extending the useful life of critical equipment.

Microsoft Dynamics 365 Manufacturing Integration with Key Microsoft Business Solutions

One of the most significant advantages of Microsoft Dynamics 365 for Manufacturing is its ability to seamlessly integrate with a wide range of business solutions, extending its reach beyond supply chain management to encompass crucial aspects such as customer relationship management, financial management, data analytics, departmental application development and artificial intelligence.

This integration provides a unified platform that optimizes operations, improves decision making and fosters innovation in Latin American manufacturing companies.

CRM Integration

Dynamics 365 for Manufacturing integrates seamlessly with the Dynamics 365 Customer Relationship Management (CRM) system, enabling companies to not only manufacture high-quality products but also effectively manage their customer relationships.

This integration helps optimize sales processes, personalize customer interactions and improve after-sales service, contributing to greater customer satisfaction and loyalty.

Financial management

The platform offers deep integration with Dynamics 365 financial management tools, providing real-time visibility into company finances, optimizing cash flow management and facilitating regulatory compliance. This 360-degree view of financial health enables companies to make more informed and strategic decisions.

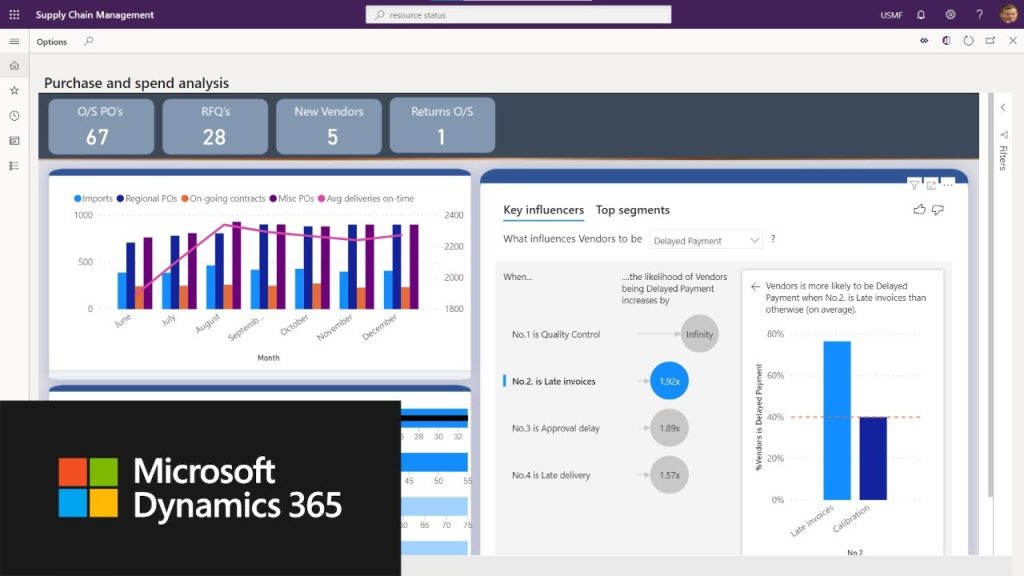

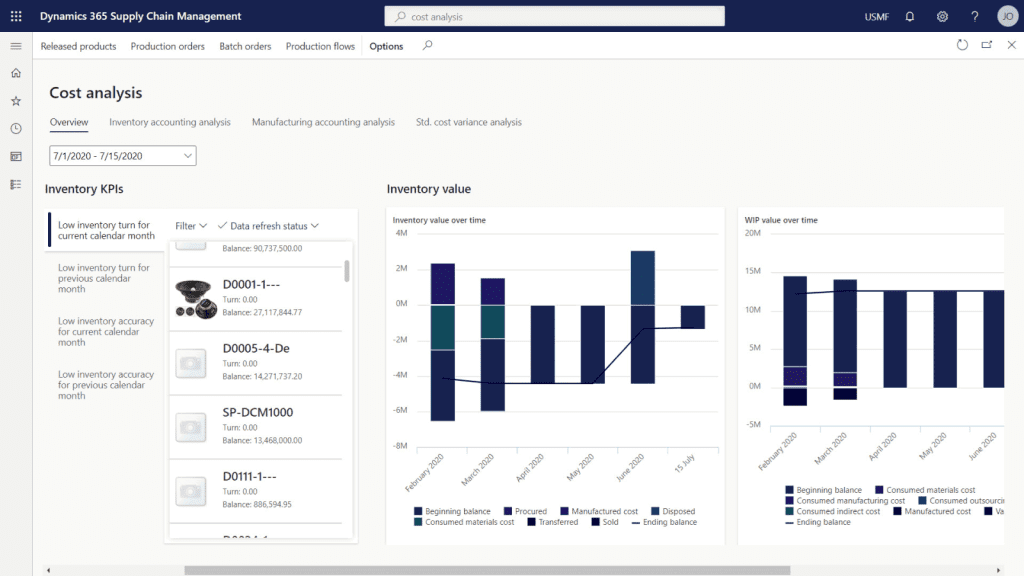

Data analytics with Power BI

Integration with Power BI transforms the way companies access, analyze and interpret manufacturing data. Users can create customized reports and interactive dashboards to monitor key performance indicators (KPIs), identify trends and gain actionable insights, all with the goal of continuously improving operational efficiency and data-driven decision making.

Building departmental applications with PowerApps

Dynamics 365 for Manufacturing leverages the power of PowerApps to enable companies to develop custom departmental applications with little code. This empowers non-technical users to create specific solutions that meet the unique needs of their departments or processes, improving business agility and responsiveness to market changes.

Artificial intelligence with Copilot

Integration with artificial intelligence through Copilot enables Dynamics 365 for Manufacturing to incorporate advanced AI capabilities into your operations. From predictive maintenance to supply chain optimization and customer experience personalization, Copilot uses data and AI models to provide intelligent recommendations, automate repetitive tasks and improve decision making.

This holistic integration of Dynamics 365 for Manufacturing with CRM, financial management, data analytics, app creation and AI, puts Latin American manufacturing companies in a privileged position to innovate, compete and grow on the global stage, while addressing the region’s specific challenges with advanced technology solutions tailored to their needs.

The future of manufacturing in Latin America with Dynamics 365

The adoption of Microsoft Dynamics 365 for Manufacturing signals a transformational change for the manufacturing industry in Latin America, not only in terms of process optimization and improved efficiency but also in the capacity for innovation and competitiveness on the global stage.

Looking to the future, Dynamics 365 is positioned as a fundamental pillar in the development and transformation of the manufacturing sector in the region, promoting the adoption of advanced technologies and sustainable practices.

Adaptation to Industry 4.0

The evolution towards Industry 4.0 is at the heart of manufacturing transformation, with the digitization of processes and the integration of technologies such as IoT, AI, and robotics. Dynamics 365, with its ability to integrate with IoT devices and apply advanced data analytics through AI, enables Latin American companies to not only keep pace with this evolution but to lead in the adoption of smart and sustainable manufacturing practices.

Customization and flexibility in production

Consumer demands for customization are reshaping manufacturing. Dynamics 365 facilitates this transition to more flexible and customized production, enabling companies to quickly adapt their operations to changing market needs without compromising efficiency or quality.

Sustainability and environmental responsibility

Sustainability has become a global imperative, and the manufacturing industry plays a crucial role in the adoption of responsible practices. Dynamics 365 supports efficient resource management, supply chain optimization and waste minimization, contributing significantly to the sustainability efforts of Latin American companies.

Expansion into new markets

The globalization of markets offers new opportunities and challenges for manufacturing in Latin America. Dynamics 365, with its integrated approach and ability to manage complex supply chains and comply with international regulations, equips companies in the region to expand beyond their traditional borders, exploring new markets and seizing growth opportunities.

Improved collaboration and data-driven decision making

The future of manufacturing in Latin America will increasingly rely on the ability to make informed decisions and collaborate effectively, both internally and with external partners. Dynamics 365, with its advanced data analytics tools and integration with collaboration platforms such as Microsoft Teams, provides a solid foundation for smarter decision making and seamless collaboration.

For manufacturing companies in Latin America, adopting Dynamics 365 means more than just implementing a new technology solution; it means embarking on a journey towards operational efficiency, sustainability and competitiveness on the global stage. The platform’s advanced features and customization capabilities are designed to meet the specific needs of the region, enabling companies to not only overcome current challenges but also prepare for future ones.